The Full Benefits of Relative Humidity Testing

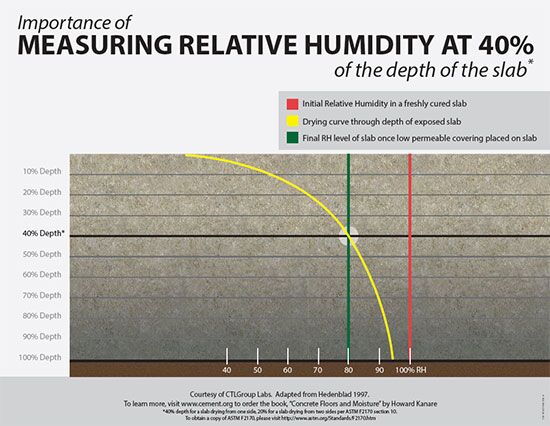

This graph shows how measuring concrete at a 40% depth provides the most accurate moisture content of the slab

You’ve heard about the unmatchable accuracy of relative humidity (RH) testing for concrete. Now you want to know about the costs, the process, and what additional benefits this method of moisture testing may provide—some of which

The many perks of RH testing include some you’d definitely expect. But there are other benefits that may not come to mind at first.

So let’s go through:

- A refresher on relative humidity (RH) testing

- 6 benefits of RH testing

- How to maximize the potential of RH testing with Rapid RH L6

A Refresher on Relative Humidity Testing

Relative humidity (RH) testing is a method of determining the amount of moisture in a concrete slab. Using sensors drilled into the concrete at 40% depth, floor installers can determine whether the concrete has reached a moisture level that’s safe for installing a floor covering on top.

Numerous studies have shown that RH testing is the most accurate and effective concrete moisture testing method on the market. This is because it measures deep within the concrete, not just the surface.

Methods that measure only the surface don’t give you an accurate picture of the whole slab and may falsely lead you to believe it’s dry enough to install a floor. This can result in a lot of problems for the flooring, both at the start and down the road.

Using the RH testing method, you’ll save time and money, increase customer satisfaction, and protect your professional reputation. Let’s go over seven of the biggest benefits of RH testing.

6 Benefits of Relative Humidity Testing

We’ll start with accuracy—the most important benefit of RH testing.

Accurate moisture measurement

As mentioned, RH testing is the most accurate way to measure the moisture levels of concrete because it detects moisture deep within the slab. Other tests only measure close to the surface.

In addition, it’s the high moisture vapor that allows alkaline salts from the concrete to move up into the flooring adhesive and degrade its effectiveness. So if you know that the concrete slab is dry enough to be ready for flooring, you won’t have to worry about adhesive breakdown, which can result in flooring failures.

As concrete flooring dries, it releases the moisture from the surface. But what’s on the surface may only be a small portion of the remaining moisture deeper in the concrete. So measuring the surface can make it seem like the slab is drier than it really is.

Beginning a flooring installation with only the information from a surface moisture reading is a steep gamble. Any moisture left deeper in the slab will keep rising to the surface and will eventually react with whatever materials are on top of the concrete. It could also cause mold growth under the floor.

Moisture could also keep traveling upward and affect the flooring itself, causing warping or twisting, delamination, or mold in the area of the floor covering.

Extensive testing1 has found that placing sensors at 40% of the slab’s thickness (or 20%, if the concrete is drying from both sides) leads to results that will predict what the moisture level will be in the future, after the floor covering is installed and the concrete has equalized.

Prevention of costly flooring failures

After RH testing, you can rest assured that the flooring you install will have a much, much lower probability of failing than if you skipped the testing. Testing ensures that the floor will be installed in the proper environmental conditions.

So if you find the underlying concrete still has too much moisture in it, you know it’s not yet ready for flooring to be installed on top. Delaying the start of an install is a whole lot less of a hassle than having to deal with moisture-related problems you’ll have to fix later.

In hardwood flooring, excess moisture can cause:

- Cupping

- Bowing

- Twisting

- Warping

- Buckling

In engineered flooring, it can cause:

- Delamination

- Mold

- Warping

- Twisting

- Failed adhesives

In tile, it can cause:

- Mold

- Failed adhesives

In carpet, it can cause:

- Mold

- Disintegration

- Failed adhesives

All of these can be very costly to repair or replace, especially if the whole slab had moisture issues.

Why not prevent it all in the first place by doing RH testing? Then you’ll know the concrete is dry enough to be ready for the flooring.

Compliance with industry standards

Part of doing an exceptional job as a flooring installer is complying with industry standards. And of those, many flooring manufacturers and installation standards uphold ASTM F2170. This standard provides the guidelines for RH testing.

If your manufacturer follows ASTM standards, you’ll want to be sure to do RH testing to stay within their guidelines to ensure that the warranty is maintained.

Cost savings

No one wants to spend time and energy scheduling and installing a floor, only to be called back later to replace it all due to moisture-related problems.

RH testing may seem like more of an expense initially. But with every concrete slab you check before installing flooring, you’re saving the money you might otherwise lose in having to redo a job.

You’re also saving the loss of money put toward a less reliable concrete test.

You’re saving the loss of time and money from having to reschedule the same flooring installation or repairs.

And you’re safeguarding the confidence your clients can have in your work—which is priceless.

Risk management

You can confidently tell your clients that you have protective measures in place to ensure the long-term quality of their floor. By using state-of-the-art concrete moisture testing before you begin installing flooring of any type, you’re significantly minimizing the risk of flooring failure or moisture-related damage or warping later on.

With the moisture in the concrete subfloor safely under control (and test results to back you up), you can confidently install a floor covering over top and know the floor will not fail because of moisture in the slab below. Other reasons for failures exist, of course, but you’ll have the big one out of the way with a simple RH test. And you’ll be able to show that any other moisture issues that could arise are not due to any negligence on your part.

Increased client satisfaction

Your work is your legacy. People take note of the work you do, and when installation is well done, your customers not only feel a sense of loyalty to you, but they will also recommend you to others.

Now that we’ve seen the benefits of using RH testing in concrete, here’s a peek at Wagner Meters’ Rapid RH L6 concrete testing system.

Maximizing the Potential of RH Testing with the Rapid RH L6

The flooring professional kit includes many components of the Rapid RH system to help you get the job done in one sweep

Wagner Meters’ Rapid RH L6 kit makes testing concrete easy, simple, and rewarding.

All you need to do is drill a hole with a ¾-inch drill bit into the slab at 40% depth. Thoroughly clean the hole with a vacuum, and then insert the Smart Sensor, after verifying that it’s functional. After 24 hours, you can begin to take readings. For a more in-depth instruction guide, you can refer to our manual.

Taking readings can be done in a few different ways. You can write them down on the enclosed report forms that adhere to the ASTM F2170 standard, or you can attach our Total Reader to the sensor and collect data on the DataMaster App.

They can be paired with your smartphone or other mobile device, allowing you to perform a wide array of functions with the data, including reading, recording, and reporting.

Three ways to monitor concrete moisture

There are three ways of using the Rapid RH L6 system, each one giving you back more of your time and making the process even more simple.

The first one is the hands-on Rapid RH kit. You place the sensor, and after 24 hours, return and manually extract the readings from the sensor and record them.

The next step up is automatic on-site. This involves the DataGrabber and the DataMaster L6 app. With this upgrade, you can set a schedule of when you want readings taken. You don’t have to be present—the DataGrabber will take these readings whether you’re standing next to it or on vacation. Once you get on-site, however, the DataGrabber will automatically send all the collected data to the DataMaster app, allowing you to review trends, look at the specific data, and make informed decisions.

The most advanced option is True Remote Monitoring. With True Remote Monitoring, the DataGrabber and DataMaster app pair with Floorcloud to allow you to view jobsite conditions from anywhere in the world when you have cellular connectivity. Every hour, 24/7, it will send current readings to the app, allowing you to evaluate it. And it will alert you if jobsite conditions go above or below the ranges you set.

If you’re trying to decide which option is best for you, consider the scenarios below.

Making the right choice

Hands-on monitoring may be the best plan if you don’t have a lot of jobsites at one time and/or you have a smaller budget. You’ll have to drive around to each one and take the measurements, but you’ll still get the accurate numbers you need.

If you have a larger crew, more jobsites, and a bigger budget, the DataGrabber and its accompanying app are a good option. You can send one crew member to zip around to collect readings on the app while you focus on other things.

And with a larger business or in a situation where you’re often gone and yet need to keep an eye on jobsites, True Remote Monitoring is your best option. From wherever you are, you can see the conditions of the concrete and remotely instruct your crews on what to do next.

Don’t Skip These Extra Benefits!

The reliability and usefulness of RH testing are perks you don’t want to ignore. The pros of this method of moisture testing are a huge part of success in a flooring installation.

RH testing is cost-effective and saves you time, money, and hassle. It ensures customer satisfaction in the long run, prevents damage, increases flooring longevity, and complies with industry standards.

What can beat all those wonderful benefits?

Nothing else compares. That’s why using RH testing is one of the best decisions you can make as a flooring installer.

Check out Wagner Meters’ Rapid RH L6 concrete testing kit to jumpstart your journey with RH testing.

- Kanare, Howard M. Concrete Floors and Moisture, Portland Cement Association, 2008.

Download the Rapid RH ASTM F2170 Checklist – Ensure Accurate RH Testing Every Time!

Jason has 20+ years’ experience in sales and sales management in a spectrum of industries and has successfully launched a variety of products to the market, including the original Rapid RH® concrete moisture tests. He currently works with Wagner Meters as our Rapid RH® product sales manager.

Last updated on February 11th, 2025